How Timely Packaging Machine Repair Can Prevent Costly Downtime

How Timely Packaging Machine Repair Can Prevent Costly Downtime

Blog Article

Exactly How to Make Sure Lasting Efficiency With Specialist Product Packaging Equipment Repair

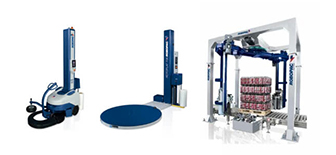

Making certain the long-lasting performance of product packaging equipments demands a calculated technique focused on expert repair services. Normal maintenance is important, as it not just addresses prompt issues yet additionally avoids prospective failures before they interfere with procedures. Recognizing the signs that suggest a device needs attention can considerably affect general efficiency. Picking the ideal specialist fixing service is similarly crucial, as it lays the foundation for effective precautionary measures - packaging machine repair. Understanding these intricacies can be the secret to optimizing your investment and boosting efficiency, but the challenges in advance may not be as simple as they show up.

Relevance of Normal Maintenance

Although many businesses prioritize manufacturing efficiency, the relevance of regular maintenance for packaging equipments can not be overstated. Appropriate upkeep is vital to ensure the optimal performance and long life of these crucial pieces of devices. Regular checks and servicing assistance recognize potential issues prior to they intensify right into substantial problems, permitting timely interventions that reduce downtime and protect against costly repair work.

Additionally, regular maintenance adds to the general security of the office. Faulty equipment can posture risks to operators, resulting in injuries and crashes. By purchasing regular examinations and servicing, companies can create a more secure atmosphere and comply with governing requirements.

In addition, well-kept devices tend to run a lot more effectively, which can enhance performance. When devices is running efficiently, it lowers the probability of production delays triggered by equipment failings. This performance equates into much better source monitoring and price savings with time.

Inevitably, regular maintenance is not simply a responsive action; it is an aggressive approach that fosters dependability and functional quality. By focusing on upkeep, organizations can ensure their product packaging equipments constantly fulfill efficiency assumptions, thus securing their investment and supporting overall service purposes.

Indications Your Device Requirements Repair

Recognizing the indications that your product packaging machine needs repair is crucial for keeping operational performance and lessening costly downtime. Early discovery of problems can avoid small problems from escalating right into significant failings, making sure a smoother manufacturing procedure.

Among the key signs of a breakdown is uncommon sounds throughout operation. If you listen to grinding, knocking, or extreme vibrations, it may indicate worn-out components or misalignment. Additionally, inconsistent efficiency, such as irregular sealing or product packaging issues, can indicate underlying mechanical concerns that need immediate focus.

One more sign is an increase in cycle times - packaging machine repair. If your maker takes longer to finish tasks than common, it may be having a hard time with internal components that are not functioning ideally. Frequent mistake messages or alarm systems on the control panel also call for investigation, as they might reveal electrical or software program problems

In addition, visible damage, such as frayed belts or rusted parts, should not be neglected. Consistently inspecting these elements can assist you capture issues before they bring about break downs. Lastly, if you notice a substantial decrease in product quality, it might be time to analyze your maker for necessary repair work to recover its performance.

Finding Specialist Repair Service Services

Begin by investigating weblink business with a tested performance history in packaging device repairs. Try to find carriers with pertinent industry experience, accreditations, and favorable client reviews. A well-established business usually has the experience to diagnose and resolve various machine concerns effectively.

Ask about the particular solutions used, including emergency fixings, regular maintenance, and parts replacement. It's vital to make certain that they utilize premium, manufacturer-approved parts to keep the stability of your tools.

Furthermore, think about the availability of the fixing solution. A business that offers 24/7 assistance can be important in times of immediate demand. Finally, get comprehensive quotes that outline labor and components expenses to prevent unforeseen costs.

Applying Safety Nets

Executing safety nets is necessary for maintaining the effectiveness and long life of your packaging equipment, as proactive maintenance can dramatically decrease the why not try this out chance of unanticipated malfunctions. Regular assessments need to be scheduled to ensure that all elements are operating ideally. This includes checking belts, equipments, and electric systems, as well as keeping an eye on and adjusting sensors software application updates.

Furthermore, establishing a routine cleaning procedure is vital. Accumulated dust and particles can hinder the maker's efficiency and bring about wear in time. Routine lubrication of moving components is likewise needed to lessen friction and stop overheating.

Training workers on proper device operation and maintenance methods additionally enhances safety nets. Staff members need to be urged to report any kind of unusual audios or performance concerns quickly, permitting timely intervention prior to small issues escalate.

Advantages of Professional Fixes

Additionally, professional fixings frequently include making use of high-grade substitute components and progressed strategies, which add to the longevity of the tools. This concentrate on quality can result in fewer break downs and minimized upkeep expenses in time. In addition, expert technicians are proficient at determining possible problems before they escalate, permitting aggressive measures that can save both time and resources.

Furthermore, engaging with professionals for fixings fosters a deeper understanding of the equipment, equipping operators to utilize the equipment better. This understanding transfer can result in improved functional methods and better overall performance.

Conclusion

Finally, the durability and effectiveness of product packaging equipments dramatically improve operational effectiveness. Routine maintenance, prompt identification of repair needs, and the option of expert repair solutions add to optimal equipment performance. Applying preventative actions and training workers further solidifies dependability. Ultimately, focusing on expert repair service services not just lessens downtime but likewise extends the life-span of tools, guaranteeing continual productivity in product packaging procedures.

Making certain the lasting efficiency of product packaging machines demands a tactical method focused on expert repair work solutions. If you observe a substantial decrease in product quality, it may be time to examine your equipment for necessary repair work to recover its efficiency.

Beginning by researching companies with a tried and tested track record in packaging machine repair work.One of the primary benefits of specialist fixings is the substantial influence they can have on the total efficiency and reliability of packaging machines. Regular maintenance, prompt recognition of repair service requirements, and the option of professional repair solutions add to ideal maker efficiency.

Report this page